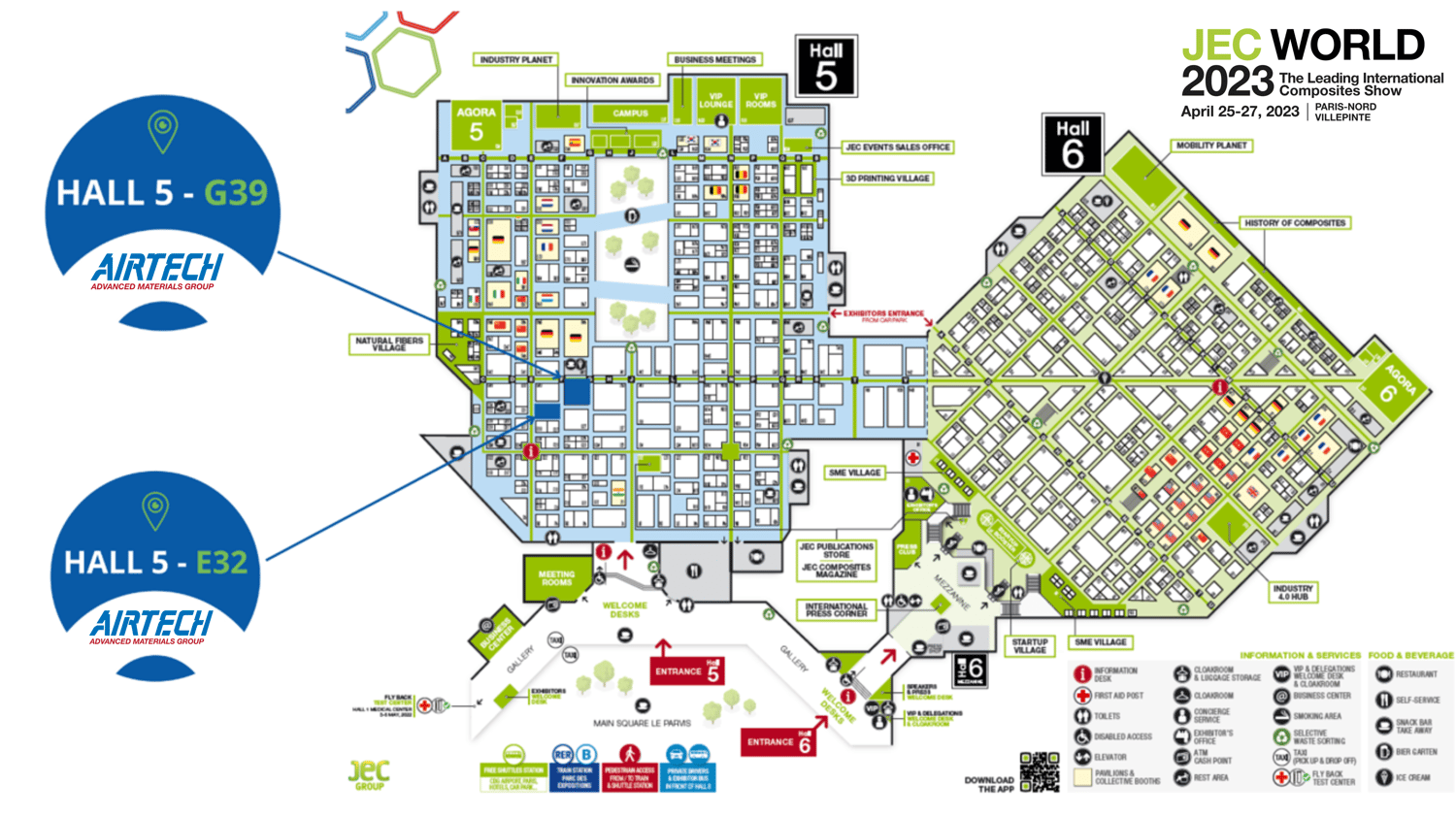

Visit our Booths #G39 & #E32 at JEC 2023 to learn more about our latest news and products and to celebrate with us the 50th Anniversary

Airtech Advanced Materials Group celebrates the 50th anniversary of excellence in the composite industry with some exciting updates and special news at JEC World! Join our team to be among the first to learn more!

We have a 50-year legacy of pioneering innovation in the composites industry, our stability, innovation, and manufacturing capabilities have earned us the reputation of being a solutions provider among our loyal customers; we look forward to demonstrating how we can help you.

Large Scale 3D Printing and Resins for Composite Tooling

Large scale additive manufactured composite tooling has quickly gained traction as a viable tooling option for rapid production of moulds, jigs and fixtures for prototyping and rate production tooling with benefits including reduced lead time, reduced cost, reduced waste and proven long term stability in autoclave at 180°C and 7 bar pressure. Airtech has successfully completed a circular life cycle for 3D printed large scale autoclave capable composite tooling. An additive manufactured carbon fibre reinforced composite mould tool produced with Dahltram® I-350CF resin has been recycled after use into usable pellet feedstock and then re-manufactured into a new usable composite tool. Dahltram® now also offer rePrint capability for circular life cycling of tooling. The rePrinted tool using recycled material will be displayed at JEC. We are also displaying several examples of composite tooling customer cases that have been 3D printed by our partners with the Airtech Dahltram® resins. Our entire line of Dahltram® resins and Dahlpram® purging compounds will be on display at JEC.

Latest innovations for the Resin Infusion Process

Airtech continues to develop products to simplify processes and shorten production time. Our new products such as new infusion meshes, Flowlease combination products range, vacuum channels, or spray adhesive were developed to answer the needs our customers face.

See our new products in action during our daily live demos at our booth #G39, at 11:00h and 15:00h and check our latest edition of the Resin Infusion brochure.

Superb surface finish and excellent laminate quality OOA prepreg products with NEXX Technologies

We are the global distributor of EndurEdge Max lines of modified epoxy prepregs fabrics and unidirectional tapes. The EndurEdge Max portfolio of modified epoxy prepregs offers performance and processing characteristics suitable for aerospace, space, Radomes and defence. The next generation of prepregs from NEXX Technologies combine state of the art resin chemistry and a unique prepreg architecture to produce high quality parts with:

- Vacuum bag only out of the autoclave curing

- Superb surface finish and laminate quality

- No-freezer storage & 400 days out-time

EndurEdge Max NT350-HT prepreg: this highly toughened resin offers high resistance to impacts. The NT-350HT offers excellent surface finish for both vacuum bag only (VBO) processing and autoclave processing. This novel prepreg product offers outstanding surface finish and laminate quality using vacuum bag only processing. Unlimited out-time (no refrigerated storage) with zero change in process parameters over time.

To visit our booth in person, be sure to register for JEC 2023!

Click here to register now and use this code EXH1089306921 for a free ticket .

.gif?width=350&height=234&name=Superb%20surface%20finish%20and%20excellent%20laminate%20quality%20(3).gif)

Need additional help? Request a meeting with us.

Where to find us:

.gif?width=350&height=234&name=Superb%20surface%20finish%20and%20excellent%20laminate%20quality%20(2).gif)