Visit our Booth #F79, Hall 12.1 at Formnext to see how your ideas could

easily take shape with Airtech's latest developments!

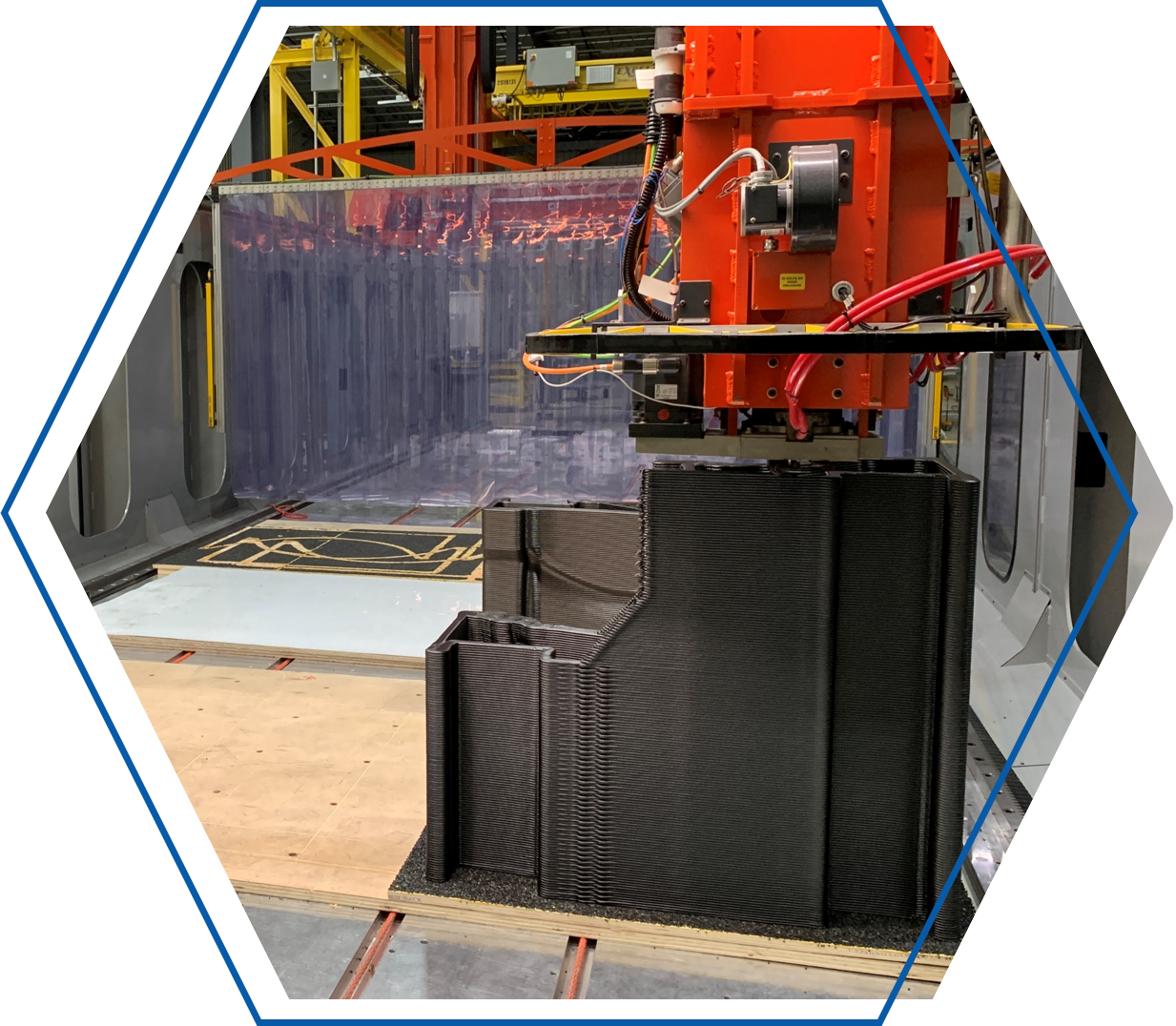

Large Scale Additive Manufacturing for Composite Tooling

It's a fact, Formnext 2021 is taking shape and we are gearing up for an exciting presence to showcase Print-Tech® - our Large Scale Additive Manufacturing tooling service for composites. On our LSAM (5 Axis) printers with integrated machining capability, located in USA and Europe, we can manufacture tooling up to 12m x 3m covering the full range of tooling applications: molds, form tools, bond tools, jigs, fixtures. Large scale tooling can be designed, tooled, and built faster without compromise quality. This is the quickest way to get you high accuracy, high performing tooling without the wait time and without excessive cost. We are also displaying several examples of composites tooling customer cases 3D printed with Airtech Dahltram® tooling resins.

High Performance Resins for Large Scale Additive Manufacturing

We will be featuring our full line of Dahltram® tooling resins and Dahlpram® purging compounds. As Airtech continues to drive innovation, development, and testing in the additive manufacturing market, it has partnered with leading manufacturers of industrial large scale 3D printers like Thermwood, Ingersoll/ Camozzi, Titan Robotics, CEAD to ensure that Dahltram® resins meet and exceed the requirements for 3D printing on all LSAM platforms.

Visit us at Formnext to find out more about the latest developments and also on how Airtech's Dahltram® range of resins and Print-Tech® in-house tooling 3D Print service took the high-performance Porsche vehicles from shop floor conception to race day reality.

Ask us for a free visitor badge here. Looking forward to meeting you at Formnext!

The high-performance vehicles carbon composite body panels were produced using 3D printed mold tooling manufactured by BBi Technical Partner, Airtech Advanced Materials Group - utilizing Airtech’s Dahltram® range of resins and Print-Tech® in-house tooling 3D Print service. Motorsports programs require rapid development cycles and, with Print-Tech®, these molds can be produced faster than ever before. This unique ability enables aerodynamic development and part manufacturing to be completed in weeks, not months.